Vital Aftermarket Construction Parts: A Buyer's Overview

Vital Aftermarket Construction Parts: A Buyer's Overview

Blog Article

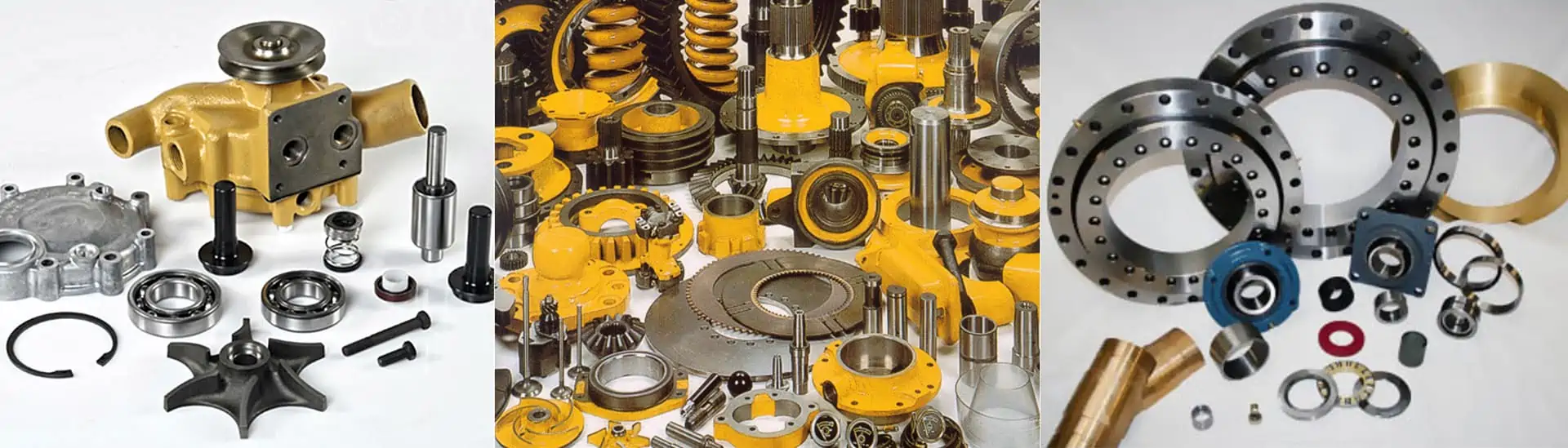

Improve Effectiveness With Top-Quality Aftermarket Construction Parts for Heavy Machinery

These components can be the unrecognized heroes of equipment performance, quietly contributing to smoother operations and enhanced performance. As machinery maintenance demands precision and reliability, a tactical strategy to selecting and including aftermarket components can make all the distinction in the world of heavy equipment procedures.

Advantages of Using Aftermarket Building Components

Utilizing aftermarket construction components uses enhanced cost-effectiveness and functional effectiveness for hefty equipment upkeep and repair service. These components, generated by third-party makers, supply an even more budget friendly alternative to original devices maker (OEM) components without compromising on quality. Among the key benefits of using aftermarket building and construction components is the cost financial savings they offer. By going with aftermarket parts, hefty machinery proprietors and operators can obtain high-grade components at a fraction of the cost of OEM parts, permitting for considerable cost savings in maintenance and repair work costs.

Furthermore, aftermarket building and construction components are conveniently offered in the market, guaranteeing very little downtime for machinery undertaking repair services. On the whole, the advantages of making use of aftermarket building components make them a valuable selection for cost-conscious hefty machinery owners looking for effective maintenance remedies.

Elements to Consider When Selecting Components

When choosing components for hefty machinery repair and maintenance, it is crucial to thoroughly think about a number of essential aspects to guarantee optimal performance and longevity. First of all, compatibility is critical. Guarantee that the aftermarket parts are compatible with the details make and model of the heavy machinery to stay clear of concerns such as incorrect fit or performance. Top quality is one more vital factor to think about. Select top-notch aftermarket parts from credible manufacturers to ensure durability and integrity under requiring operational conditions. In addition, think about the reputation of the vendor. Select a relied on vendor with a performance history of providing premium aftermarket components and exceptional client service to guarantee a smooth acquiring experience. Cost-effectiveness ought to likewise be taken into account. While cost is necessary, prioritize worth over the most affordable cost to avoid compromising on quality. Lastly, think about the availability of parts. Choose a supplier that preserves sufficient stock levels to make certain timely shipment of the called for parts, minimizing downtime during repair and maintenance tasks. By very carefully evaluating these factors, you can make enlightened decisions when picking aftermarket components for heavy equipment upkeep and repair service.

Value of Routine Upkeep

Taking into consideration the vital duty that quality aftermarket components play in ensuring optimal performance and longevity for hefty machinery, the importance of regular maintenance can not be overstated. Routine upkeep is vital for keeping heavy machinery operating at peak efficiency while decreasing the risk of unforeseen break downs. By performing regular inspections, oiling moving components, and changing worn-out elements in a prompt manner, operators can protect against costly downtime and extend the lifespan of their tools.

In addition, normal maintenance not only enhances the efficiency of heavy equipment but also adds to work environment security. Properly maintained machinery is less likely to malfunction or create mishaps, protecting both operators and bystanders. Furthermore, proactive maintenance techniques can assist determine potential issues before they rise into significant troubles, conserving time and cash in the future.

Enhancing Equipment Performance With Upgraded Components

To optimize heavy machinery performance, incorporating upgraded components is a strategic method that can significantly enhance efficiency and reliability. Updated parts are developed to fulfill greater criteria of top quality and durability contrasted to common OEM components, offering enhanced efficiency capabilities. By purchasing premier aftermarket components, such as innovative hydraulic systems, enhanced tracks, or high-performance engine parts, hefty equipment drivers can experience enhanced performance and extended equipment life expectancy.

One key benefit of you could check here utilizing upgraded parts is the capacity for raised productivity. Updated parts commonly feature advanced innovation or materials that can take care of heavier workloads, run a lot more successfully, and need much less maintenance. This boosted efficiency can bring about better result levels and decreased downtime, ultimately making best use of the total effectiveness of the machinery.

Moreover, updated components can additionally contribute to cost savings in the lengthy run. While the preliminary investment in high-grade aftermarket components might be greater, their boosted durability and performance can cause less substitutes and repair services, conserving both time and cash over the life expectancy of the equipment. Ultimately, enhancing equipment performance with updated components is a wise financial investment that can cause raised effectiveness, dependability, and cost-effectiveness.

Cost Savings and Long-Term Value

Maximizing cost financial savings and lasting worth is a vital goal when buying aftermarket construction parts upgraded aftermarket parts for heavy machinery. While the initial financial investment in high-quality aftermarket parts might appear greater than going with less costly options, the lasting advantages much surpass the ahead of time expenses. High-quality aftermarket parts are made to be long lasting and dependable, minimizing the frequency of replacements and minimizing downtime for maintenance, inevitably translating right into substantial expense savings in time.

Furthermore, spending in premium aftermarket components can boost the general efficiency and performance of hefty machinery, leading to enhanced efficiency and smoother procedures. By picking aftermarket parts from trustworthy providers that follow market standards, you can make certain that your machinery operates at its ideal degree, reducing the danger of unexpected failures and pricey fixings.

Final Thought

In conclusion, aftermarket building components provide numerous advantages such as price savings, boosted performance, and long-term value. By thinking about variables like dependability, compatibility, next and top quality when choosing components, machinery effectiveness can be significantly improved. Routine maintenance and upgrades with high-quality parts are essential for making certain ideal performance of heavy equipment. In general, purchasing aftermarket construction components is a sensible decision for making the most of efficiency and efficiency in building and construction operations.

As equipment maintenance needs accuracy and reliability, a strategic strategy to selecting and integrating aftermarket parts can make all the distinction in the globe of heavy equipment operations. - aftermarket construction parts

These parts, created by third-party makers, supply a more budget friendly choice to initial tools maker (OEM) components without endangering on quality. By choosing for aftermarket parts, hefty machinery proprietors and operators can obtain high-quality parts at a portion of the expense of OEM components, permitting for considerable savings in upkeep and repair service costs.

Updated parts are designed to meet greater standards of high quality and resilience compared to conventional OEM components, offering boosted performance capabilities. By investing in top-notch aftermarket parts, such as advanced hydraulic systems, reinforced tracks, or high-performance engine parts, hefty machinery drivers can experience enhanced functionality and prolonged machinery lifespan.

Report this page